Manufacturing has always evolved alongside technology, from mechanisation to automation and now intelligent systems. Today, the pace of change is accelerating as artificial intelligence moves from experimental projects into everyday operations. For manufacturers facing rising costs, skills shortages and pressure to improve efficiency, AI is no longer a future concept but a practical tool delivering measurable results.

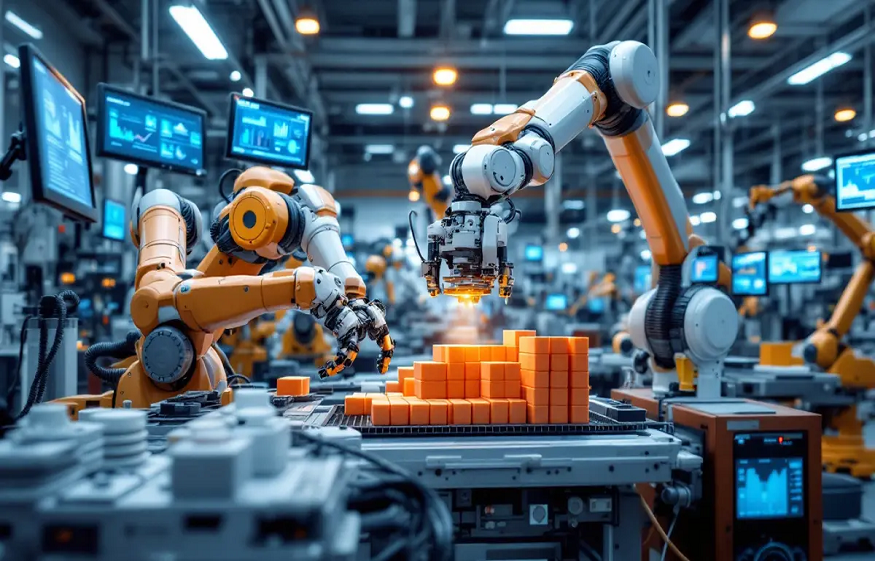

This shift is driving growing interest in AI Manufacturing. By embedding intelligence into machines, systems and processes, manufacturers are finding new ways to improve productivity, reduce waste and make better decisions across the entire value chain.

Why manufacturing is primed for AI adoption

Manufacturing environments generate vast amounts of data. Machines, sensors, supply chains and quality systems continuously produce information that, until recently, was underused or analysed retrospectively.

AI changes this by enabling real-time analysis and prediction. Instead of reacting to problems after they occur, manufacturers can anticipate issues, optimise performance and respond faster to changing conditions.

Several factors make manufacturing particularly suited to AI:

- High volumes of structured operational data

- Repeatable processes ideal for pattern recognition

- Clear performance metrics such as downtime, yield and defect rates

- Increasing connectivity through industrial IoT

Together, these conditions create fertile ground for intelligent automation and decision support.

Moving beyond traditional automation

Traditional automation focuses on executing predefined instructions. While effective, it lacks flexibility when conditions change. AI introduces adaptability, allowing systems to learn from data and improve over time.

For example, AI-driven systems can adjust production schedules dynamically based on demand forecasts, machine availability or supply chain disruption. Quality control systems can learn to detect subtle defects that static rules would miss. Maintenance can shift from reactive or scheduled approaches to predictive models that reduce unplanned downtime.

This evolution transforms automation from rigid execution into responsive optimisation.

Practical applications across the factory floor

AI in manufacturing is not limited to one area. Its impact spans multiple stages of production and operations.

Predictive maintenance is one of the most established use cases. By analysing sensor data, AI models can identify early signs of equipment failure, allowing maintenance teams to intervene before breakdowns occur.

Quality inspection is another key area. Computer vision systems powered by AI can inspect products at speed and scale, improving consistency while reducing reliance on manual checks.

Production planning benefits from AI through improved forecasting and scheduling. Algorithms can balance competing priorities, optimise batch sizes and reduce bottlenecks more effectively than manual planning alone.

Supply chain optimisation uses AI to anticipate demand fluctuations, manage inventory levels and identify risks, helping manufacturers remain resilient in volatile markets.

Data as the foundation of success

AI is only as effective as the data it relies on. For many manufacturers, the challenge is not lack of data, but fragmented, inconsistent or inaccessible information spread across legacy systems.

Successful AI adoption begins with data strategy. This includes improving data quality, integrating systems and ensuring information flows reliably between machines, platforms and teams.

Modern manufacturing increasingly depends on cloud platforms and advanced analytics to centralise and process data at scale. This foundation enables AI models to deliver insights that are accurate, timely and actionable.

Empowering people, not replacing them

A common concern around AI is its impact on jobs. In manufacturing, AI is far more likely to augment human roles than replace them entirely.

By automating repetitive analysis and routine decision-making, AI frees skilled workers to focus on higher-value tasks such as problem-solving, innovation and process improvement. Maintenance engineers can spend less time firefighting and more time improving reliability. Quality teams can focus on root cause analysis rather than manual inspection.

Crucially, successful implementation involves training and change management, ensuring staff understand and trust AI-driven insights rather than seeing them as a threat.

Overcoming barriers to adoption

Despite clear benefits, many manufacturers face obstacles when implementing AI. Legacy infrastructure, skills gaps and uncertainty around return on investment are common challenges.

Starting small can be an effective approach. Pilot projects focused on specific pain points allow organisations to demonstrate value quickly and build internal confidence. From there, AI capabilities can scale across operations.

Leadership alignment is also critical. AI initiatives need clear ownership, realistic expectations and integration with broader business strategy rather than existing as isolated experiments.

Cybersecurity and resilience considerations

As manufacturing systems become more connected and intelligent, cybersecurity becomes increasingly important. AI relies on access to operational data, which must be protected from disruption or compromise.

A robust security approach ensures that innovation does not introduce new vulnerabilities. This includes securing industrial networks, protecting cloud platforms and managing access controls across systems.

Resilience is equally important. AI systems should enhance operational stability, not create single points of failure. Careful design and monitoring ensure that intelligent automation strengthens rather than weakens production environments.

Measuring value beyond cost reduction

While cost savings are a major driver of AI adoption, value extends beyond immediate financial returns. Improved quality, reduced waste, faster decision-making and greater flexibility all contribute to long-term competitiveness.

AI also supports sustainability goals by optimising energy use, reducing scrap and improving resource efficiency. As environmental performance becomes a strategic priority, intelligent systems play a growing role in meeting regulatory and customer expectations.

Measuring success across these dimensions provides a more complete picture of AI’s impact.

Preparing for the future of manufacturing

AI is not a one-time upgrade but an ongoing capability. As algorithms improve and new applications emerge, manufacturers that invest early build experience and maturity that compounds over time.

The future factory is not defined solely by machines, but by how effectively data, technology and people work together. AI acts as the connective tissue, turning information into insight and insight into action.

Manufacturers that embrace this shift position themselves to respond faster to change, innovate more confidently and compete in increasingly complex markets.

Final thoughts

The integration of artificial intelligence into manufacturing marks a significant step forward in how products are designed, produced and delivered. By moving from reactive operations to intelligent, data-driven systems, manufacturers can unlock new levels of efficiency, resilience and insight.

However, achieving this requires more than technology alone. Strategy, data foundations, skills and security all play a role in successful adoption. For manufacturers looking to explore and implement AI with confidence, BCN provides expert guidance and practical support, helping organisations turn AI ambition into real operational advantage.